Moen shower faucet provides no cold water, only hot

A common issue with older Moen shower faucets is only cold, or only hot water coming out of the faucet or shower head. This often happens with showers that are not used very often, or where the water supply is particularly hard or has high levels of contaminants. If you search the web for help, the most often suggest is to replace the main cartridge (part number Moen 1225 or 1200). However, this is most likely not the source of the issue.

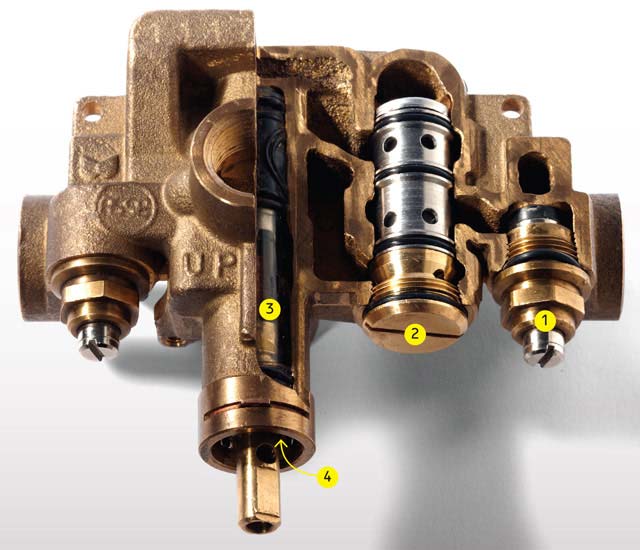

If you remove the shower faucet knob, and remove the cover behind it, you should see something like the image below. This is a Moentrol 3570 valve, there are other similar model numbers.

Within the valve is what is called a balancing spool. This balancing spool valve contains a piston which moves back and forth maintaining a given temperature even if the pressure on the cold side is reduced, for example someone flushes a toilet when the shower is in use. It prevents a sudden blast of hot water which can lead to burns. When you suddenly experience only the cold or hot water flowing regardless of where you set the flow handle, this valve is almost always the culprit.

The piston which is inside the balancing spool will get stuck in one position or the other. When this happens, it essentially shuts off flow to either the hot or cold side. Poor water quality and age will eventually cause the piston to get stuck in its bore. The balancing spool (part number Moen 1423) can be seen clearly in the photo below.

The first step in repairing the balancing spool valve is to remove it. You will need to use a VERY large screw driver to unscrew the valve (number 2 above). Make sure you shut off your water first! You can also use a straight-edge piece of metal clamped in vice grips if you do not have a large enough screw driver. Spray the outside of the screw with Liquid Wrench or other penetrating oil in advance of your attempt, it can be difficult to loosen. If you are lucky, the valve will come out with the screw. But, most likely the top of the spool will separate, like in the photo below.

If this happens, you will need to retrieve the stuck piece. The way that I accomplished this was to soak it in Liquid Wrench for an hour before my attempt. I inserted a screw driver down into the piston and tried to lever it out, tapping with a hammer at the same time. I then bent a piece of metal rod into a hook shape and fished it inside and caught it against one of the holes in the body of the spool. Using a pair of vice grips I pulled until it came loose. This may take some work, so be patient.

Once removed you have two options, replace with a new one, which is not cheap, retail price is between $55-95.00. Or, you can usually successfully clean the spool. To do this, remove the round piece of metal at the back of the valve (seen above). Just slip a small screw driver into the gap and twist it out. Then tap the piston out of the bore. I used a socket to support the back of the spool, and used a hammer and screw driver to tap it out.

Next, you want to use fine sandpaper to clean off the piston journals, and the inside of the bore of the valve. Get aggressive, you want the bore and journals to be polished clean. Work the piston back and forth in the bore until there is absolutely no sticking or binding. Then apply plumbers grease and reassemble. Turn the water back on and test the faucet, you should now have hot and cold water, and just saved yourself a couple hundred dollar repair bill.

- Whirlpool Duet Dryer GEW9250PW1 will not turn on, no lights displayed on control panel.

- How do you extract POST form data and file uploads in node.js?

After reading many other suggestions that recommended change the cartridge, I found out this very illustrative recommendations that made more sense to me. I followed the steps recommended here and the problem is now solved.

Wonderful strategy of how to fix a Moen single handle faucet that no longer works correctly – giving only cold or hot water. I had two showers that both suffered this problem after 6 months of non use – they only gave hot water, no cold water. I offer the following tips. Beneath the cap is a large O-ring, so using a powerful petroleum based lubricant (WD-40, Liquid Wrench, etc.) is not needed and counter productive, as it may ruin the O-ring over time. Instead, use a hammer and a large flat head screwdriver to repeatedly tap around the periphery of the cap. Then, use the flat blade like a chisel, place it into the slot of the cap, and begin striking gently at an angle at the slot of the cap, in a counterclockwise direction, as if you were trying to unscrew it with the screw driver. It will move ever so slightly. Keep tapping and when you have moved it about 1/12 turn, you will find that you can easily unscrew the cap the rest of the way by placing the screwdriver into the slot and turning the cap counterclockwise to unscrew it. In both instances for me, the cap and the balancing spool came out together in one piece. I did have to grip the cap with a Vise-grip plier to pull it the rest of the way out of its housing. Once out, if it is in one piece, then don’t take off the top cap. Instead, insert a small flat blade screwdriver into the gap betwen the bottom cap and the body of the balancing spool and gently work the blade around, prying ever to slightly, to slowly pop off the bottom cap without deforming it. With the bottom cap off, you can now use a jewelers flat blade screwdriver to gently prod the piston out through the bottom of the spool housing by gently prying it down from the outside by using the holes drilled into the piston. At some point, you will give up prying it down using the holes on the outside of the piston, and then begin pulling it down by pulling against the holes inside the piston. I used the jewelers flat blade screwdriver for this. Once the piston is about 1/4 the way out of the bottom of the balancing spool, you can grasp it by hand and pull it out. Both my pistons were in excellent shape, and would move freely within the piston bore since there was no corrosion. I used a good silicone (non petroleum based) lubricant to lubricate the piston, and then reinserted it into its bore. Be careful here. I did not measure it with a micrometer to see, but the piston looks totally symmetrical end for end, so be careful to maintain the original orientation and don’t accidentally flip it end for end, because you won’t be able to tell one end of the piston from the other. Once the piston was lubricated and reinstalled into the bore of the balancing spool, I placed the bottom cap back in position and gently tapped it with a hammer to reseat it. Then I applied more silicone lubricant to the threads of the cap and the O-ring beneath them, pushed the spool back into place in the shower valve, and then tightened the cap to where it bottomed out on the brass housing — but did not over torque the cap. No need to, as it relies upon the O-ring for its seal and not torque applied to the threads.

Hey- Thanks for the post. Was exactly what I needed. Very good instructions and pictures. Was better info than calling the factory. Thanks from Luke Doubler in Minnesota.

This just saved me money and a ton of time. Directions were easy to follow and worked as expected. Thanks!

Excellent advice and technique in the prior suggestions. The photos are very helpful. Apparently it’s fairly common for the brass cap to disconnect from the metal sleeve if the sleeve is stuck while you unscrew the cap, likely from calcium buildup. This is a design flaw Moen should fix but hasn’t in decades. The “break” happened on two valves I had to repair back-to-back.

There are two types of pistons in the 1423 balancing spool. The older is stainless steel; the newer is plastic. There’s a slight difference in diameter with the SS spool being a little larger, which can impact the ease of removal. Unfortunately both were very difficult to remove. The difference is important because the plastic piston can easily be damaged if you use pliers to grab it.

Removing the brass screw was difficult but not impossible. Lubricate the threads first and allow time to penetrate. Using a heavy-duty 1 inch chisel as a screw driver, with a crescent wrench for leverage, worked well. The piston in both cases protruded enough that I could grab and pull out with some effort. The plastic piston broke in the process.

Removing the SS spools was almost impossible and took hours. Overall I spent about 6 hours trying to remove 2 spools in 2 separate valves. There’s not enough lip of the SS cylinder exposed after the brass screw is removed to grab with needle nose. I tried hooks, wires, screwdrivers without success. I finally used a 1/2″ internal pipe wrench (~$11 for a set of 3 @ HD) to help remove the spool. The internal pipe wrench would grab the inside sides of the SS cylinder and finally broke the lime deposits and allowed the cylinder to rotate. With enough rotating and pulling while turning to keep the wrench tight, the cylinder came out enough to grab with needle nose. More pulling and a small vice grip could finally lock onto the lip. There are 3 O rings on the outside of the spool. It’s the resistance of 3, then 2, then 1 that you have to overcome to remove the spool, so it gets easier as each comes out.

By this point I just wanted the ordeal over. I squirted in Lime-Away, reamed out with a wire brush (used for copper pipe soldering), lubed the O rings with silicon grease, slapped in new 1423s ($65 Amazon), tested and closed up. If I has started with the internal pipe wrench, maybe replacing a stuck cylinder would have taken only an hour. Overall it was a very frustrating experience and annoying because Moen could easily make spool removal a simple process by strengthening the brass/SS connection to ensure it remains one piece during unscrewing.

Some mentioned cleaning and reusing the old spool. I suppose you can. However, if the spool broke into two parts as mine both did, the SS cylinder part will be very difficult to remove again after re-insertion. After the effort I put into this and hopefully avoiding a future problem, new spools were the way to go.

Procedure and discussion were VERY helpful. The brass cap broke off my SS unit on extraction. I made 3/4 wide steel “screw driver” from flat stock to remove cap…. worked well. Made custom extraction tool from rod stock and nail using drill press, bench grinder, hydraulic press, and Dremel tool (fortunately had all this stuff!)

Aug 2017

I had no cold water flow at all; I replaced the spool and now have about 30% flow on the cold side versus 100% on the hot side. Anybody else run into this or have a suggestion? Already changed the cartridge before I found this article.

A million thanks for the detail and pictures, to Luke as well. I moved into a house which had been vacant for some time, and this proved to be the issue. I suspect my cartridge was not as fused up as others described above, but here’s what worked for me:

I did not use a lubricant to unscrew the brass cap, I started by tapping it patiently with a large screwdriver and hammer. The chisel and vice grip technique got it moving.

Once extracted — it came out as one piece — I used a set of small extraction tools with various hooks and angles to remove the inner spool, working from the openings on the side.

Following the above advice, I cleaned with a small wire brush and applied silicon lubricant before replacing. Its working fine now…

I have a Moen single-handle faucet in my bathroom. When I went to bed, everything was working fine. We did have -9 degree temps, and I opened the cabinet doors, just as a precaution. I woke up this morning with no cold water coming out the faucet. Hot water works OK, just no cold. My wife’s sink is good with hot and cold water. I replaced the cartridge with one sent from Moen for my model faucet, but still not cold water.

Lewis, same thing for me, it was -15 F and my GF just said only got came out was hot. Wish I took the first shower of the day to hear/see what happened. Mine looks newer, I don’t have all those valves and options on my Moen and my water shut off is a bitch to get to.

This guy is my new hero….he should write a book and have people meet weekly to discuss it….then donate money to him….thank You, thank You, thank you

how much does this repair cost for a plumber (approximately). I just can’t….#nothandy

Very accurate description of my problem with our little used second shower. Also tagged such that it turned up at the top of our Google search and I didn’t have to go through a lot of useless, unhelpful, profit oriented sites to find this.

The pictures, particularly the cutaway view, are extremely helpful. BUT the absolute most helpful thing about this entire article is the warning that the balancing spool stands a good chance of breaking when you try to remove it. That, in and of itself, was enough to dispel any Saturday morning DIY Fixit man hero fantasies I might’ve been harboring. We only have one on/off valve for the water in the entire house. So if anything happened and I was not able to finish the task today we would be entirely without water until such time I could get a plumber in here.

Thanks to that warning I was able to make a wise decision and direct my attention to the tasks which I can safely accomplish without inconveniencing my family.

Great stuff

My problem is no water at all

I changed the cartridge and cleaned the the spool no success

With out the cartridge I can open the valves and water pours out ????

Great article very detailed everything you said is true if you just follow the directions I just wish I would found it earlier.. we all know how frustrating these home projects can be

Finally finished replacement. I wasted over $100 on inside pipe wrench sets. The 4 piece kits have 3/8″ as the smallest size, which is too large to fit inside the moen unit. I then ordered one from zoro.com that had 6 pieces. I thought the 1/4″ one was going to work but it is slightly too small.

The solution was to buy a couple of $6 kits of awls from Walmart. Using 2 awls with 90 degree bends on their points I hooked one in the holes on each side of the Moen unit and got it pulled out. I had also used some Liquid Wrench and some cleaner that cuts through calcium build up to soak it, which may or may not have helped. Hard to say. The angled awls were the key.

Not sure if this test will work or not. If I turn off both hot and cold stop check valves and remove the main center cartridge and open the cold water and it comes out then it is the main center cartridge and not the balancing spool, same if I do the hot. If I put the main center cartridge back in and open the blocked stop check valve and nothing comes out then it is the main center cartridge. In my case I am getting no cold water. Might save time and money buying parts.

Just to learn about my valve. I may cross the bar before service is needed. waiting on stuff to complete the project.

I had no cold water in shower and I replaced the cartridge and that did not help. I found out it was a stuck balancing spool I did not want to get in the job of replacing the balancing spool so I got my hammer out and tap on the valve and that freed it up that saved me a lot of work and if anybody have the same problem try the hammer first to see if that solved the problem.

Reply to Jeff – after replacing 1225 cartridge and balancing spool – had 30% only or less flow on cold water side. I removed both of these again and put a rag with white vinegar to help clear the flow tube between cartridge and spool. this initially did not work so I tried to snake out the hole with a hanger. This seemed to do the trick. I still think I have some rubber that came off old cartridge and partially blocked flow tube. I am not sure if it is removed but it at least is not blocking the flow anymore. Seems to work fine after reinstalling both cartridge and spool.

So glad I found this post! Extremely helpful, and solved my issue of only hot water from the faucet. I had tried everything, including switching out the cartridge, and was ready to throw in the towel and call a plumber/install a new valve when I stumbled upon this. Thank you!

My experience, for what it’s worth… Once I was able to get the spool to budge (using a combination of WD-40, lightly hammering a screwdriver in a counterclockwise fashion as a previous commenter mentioned, and a large piece of metal in vice grips), the top of the spool popped off with the rest still stuck inside. Was about to attempt to extract the rest, but then thought I’d try agitating the spool in place; worked like a charm! Didn’t take too much agitation to get it rotating and moving back and forth again. Put the cap back on, sealed everything back up, and I’m back in business! A little context, I recently purchased this house from an estate, and the house had been vacant for a few years; hoping with regular use, the balancing spool won’t freeze up on me again. If it does, I know what to do now!

Thanks again!

I’m taking this in stages. I don’t want to shut off all water to the house until I’m ready to go ahead and the family knows they may be without for several hours. So today I just made sure I can unscrew the brass cap. First I prepared by buying a screwdriver with a 3/8″ wide blade – ~$6 at Lowe’s. I used a touch of vinegar in case of calcium buildup, and tapped gently around the cap with a screw driver and hammer for 3 minutes. I adjusted an 8″ crescent wrench to fit the screwdriver handle and used a little pressure to break loose the cap. Then I put it all back together to wait for the main event next weekend.

Following Tom’s post, I checked to see if the tapping broke the spool loose Not as lucky, dang.

Have a Moen that uses the 1222 cartridge. Getting only a drip of cold water….hot is fine even after replacing the cartridge. This shower is used daily. I did just put a new wand at the top and removed the pressure regulator inside. I have well water. Even thru the spout all hot, only drips of cold (I have PEX with a manifold so I was able to shut off only the hot for testing). Will get into this and see what happens

Ok….different setup….no valve body…..simple brass hub that water lines and cartridge go into. See my last message above. When I discovered I had a simple hub I simply removed the cartridge and turned on the cold at the PEX manifold to see if I had cold supply to the hub……yep. How can I replace a cartridge that was only replaced about 3 or 4 months ago (for a different reason) with a brand new cartridge and experience the exact same problem as if I didn’t replace it? They were both Moen brand (not aftermarket) 1222 cartridges? I know anything is possible but this seems extraordinarily unlikely…..any suggestions would be much appreciated.

Ok,…..a bit of important information to know about the Moen 1222 Posi-Temp cartridge. The cold side won’t work unless there is pressure on the hot side…..so if your testing your new cartridge by just turning on the cold supply after installing your new cartridge the cold just trickles out. Once the hot supply is also turned on, whatever is going on inside the cartridge allows the cold to flow freely. So don’t waste hours trouble shooting but testing just cold or hot….I’ve already done that for you.

Thank you so much for this post! A plumber I contacted was unwilling to fix the valve saying it was old and he would only replace the whole thing which would mean opening some of the wall and removing some of the tiling. This post was spot on! I didn’t even know about balancing spools before.

My valve was not Moen, but American Standard from the 80s. The procedure was the same. Surprisingly, the balancing spool was quite easy to remove with groove pliers (https://smile.amazon.com/Channellock-430-Straight-Heat-Treated-Reinforcing/dp/B00002N5JF) after applying a bit of WD-40. The inner spool would not budge so I submerged the whole thing in white vinegar for a couple of hours. After that I was able to pry it out with a small allen key (grabbing by one of the holes). Then I used a scour pad with a bit of Brasso (https://smile.amazon.com/gp/product/B00D600PLA) to clean the deposit off and washed and dried everything with a cloth. After that everything was moving smoothly and when I inserted it back, bam, cold water was flowing normally.

Thank you again!

This solved my problem too. Great detail- many thanks for sharing especially because getting a plumber these days takes weeks and costs hundreds. One note is that on some valves the spool can be located on the hot water side of the valve (in case that throws anyone). Also it is. It intuitive but both supplies (hot and cold) are routed to the spool before then being routed to the cartridge. This is obvious in hindsight but to my lay eyes was not intuitive when originally diagnosing the issue. Thanks again for sharing.

Jimmy, this article may be 7 years old, but I’m incredibly happy you wrote it, and that I was bale to find it! I have replaced my cartridge three times in the past three years, hoping that each replacement would magically bring me some cooler water temps. There was about an 3/8″ section on my handle that provided a decent temperature to shower with, but at the expense of about 1/2 of the normal pressure. Otherwise, it was HOT water no matter what. I can’t wait to go buy this spool after I get off work and get it home to start this process. And I appreciate the information from you and all the other comments about the difficulty of doing this. This will save me some aggravation as I’m going through these steps.